How Does Waterjet Cutting Work? A Complete Guide

- pawankumar39

- Nov 22, 2022

- 4 min read

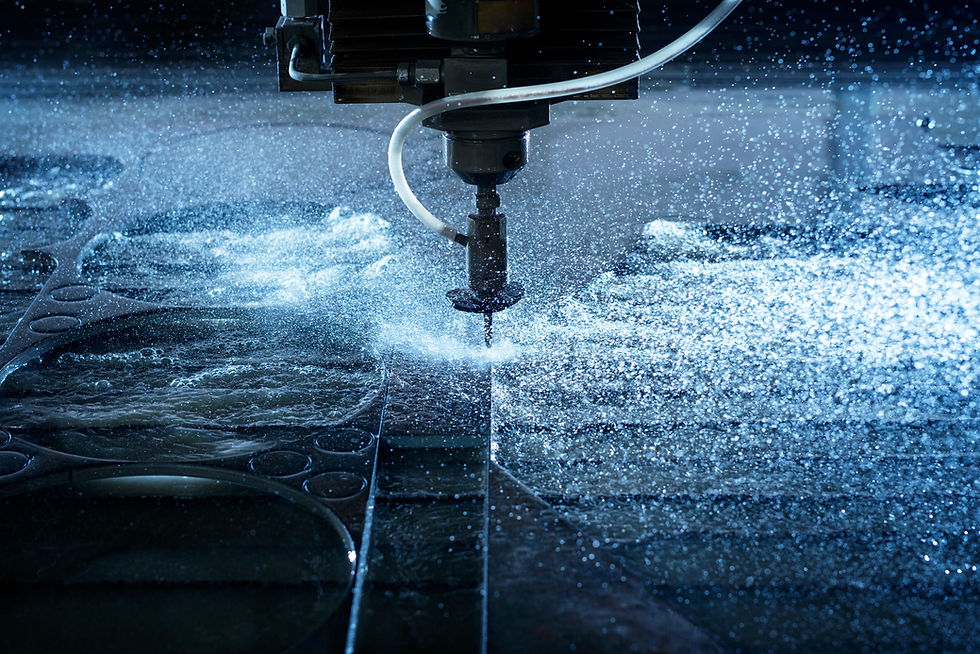

May 5, 2019 by Bob Wilson An almost impossibly fine jet of water streams from a choked down nozzle.

As you watch, the water slices through a 1/4″ panel of steel, creating an intricate part, all shaped under CnC controls.

And you’re left wondering, “How did that just happen?”

If you’ve ever wanted to know how waterjet cutting works, you’re in the right place. We’ll break it down to help you understand this powerful and precise manufacturing process.

Under Pressure

The main mechanism which powers a waterjet is the extreme pressures that the water is placed under. The pressures in a jet can reach to 90,000 PSI.

For comparison, a pressure washer usually only reaches about 2,000 and already have a reputation for injuring people who aren’t careful.

This incredible pressure is the reason that waterjet cutters can easily cut through the majority of materials. Water is rather dense and with the pressure behind it few surfaces stand a chance.

The high pressure has another advantage: waterjets remove a minimal amount of material due to an incredibly tiny kerf. The material removal area for a waterjet is usually in the range of 0.5mm to 1.0mm, allowing preservation of expensive feedstock and a remarkably fine end product.

Abrasive Action

Water, by itself, isn’t able to cut through everything. For materials like steel, titanium, and stone there’s an additional part of the waterjet process to take into account.

Waterjets can be used with nozzles that add a measured amount of abrasive to the stream of water doing the cutting. While generally comprised of almandine garnet, pretty much every single type of abrasive has been tried at one time or another.

The abrasives are finely selected for particle size and shape to make them suitable for the cutting application at hand. It’s a subject unto itself.

The important thing is that the addition of an abrasive into the waterjet’s nozzle can allow it to cut… well, anything softer than the abrasive being used. In specialized applications, waterjet cutters can make short work of materials that other cutters can’t even touch like granite and exotic metal alloys.

In essence, the whole process is a quicker version of the erosion seen in nature. As the water carries the abrasive, small amounts come away with the water and begin to create a channel.

The same force which made the Grand Canyon is harnessed in a waterjet, just sped up by an incredible rate.

Computer Controls

Early waterjets had a serious problem: they were hard to control. By their very nature, a jet of water has a tendency to bend, warp, and otherwise not want to cooperate with the process of shooting straight through a material.

For some time they were considered a tool of last resort. You really didn’t have many options when it came to cutting ultra-hard materials like tungsten back then, but they were generally looked upon as an imprecise but sometimes necessary tool.

In the modern day, nothing could be further from the truth.

So, how does a notoriously hard to control jet of water become one of the most precise machining processes in the world?

Computers.

All modern waterjets are controlled by a computer. There’s a surprising amount of programming that goes into a waterjet, there’s much more to it than the nozzle simply following a file to glide over the work surface.

Instead, the computer programs work to predict the shape of the jet as well as guiding it over the surface as you’d find with any CNC machine. The truth is that waterjets were really only developed as precision tools alongside PCs.

There was, until recently, one major problem still facing those who wanted to use waterjet machining processes.

Getting Third Dimensional

Even with the powers of PCs behind them, early waterjets were mostly restricted to cutting out 2D patterns. It took more advanced machinery and computing power to bring the process full circle.

Modern waterjets can cut a vast array of 3D shapes by angling the nozzle. The process requires an intense level of computing power, predicting the shape and direction of the stream while it’s moving on three different planes is no easy task.

They’re not perfect for the task just yet, but the three-dimensional capabilities of waterjet cutting are increasing all the time.

Why Waterjet Cutting?

Cutting with water can seem like a win, but it’s obviously slower than some of the other manufacturing processes out there.

Unsurprisingly, waterjets offer a number of extra advantages over processes like laser or plasma cutting:

No heat warping

Capable of cutting reflective surfaces

Can cut exotic materials like tungsten and granite

Relatively environmentally friendly

Good finish after cutting

Anytime you’re looking for industrial manufacturing you should take care in choosing the process used.

Waterjet cutting is best for materials which are flat, need to be precision cut, and are in harder than average materials. It’s a slower process than heat-based methods like laser cutting as well, so parts will take longer to arrive if you hire a manufacturer to bring your vision to life.

Have More Questions About Waterjet Cutting?

Waterjet cutting is awesome, there are no two ways around it. Between harnessing the power of erosion to make tightly manufactured parts and the ability to cut through materials other processes won’t even cut… they’re just a wonder all the way around. If you’re looking to get precision parts made, then consider using a waterjet for your next project. If you have any questions about the process or want to see if we’re a good fit for your next order, why not contact us?